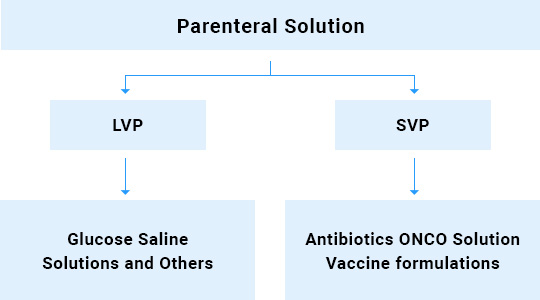

Parenteral Solution

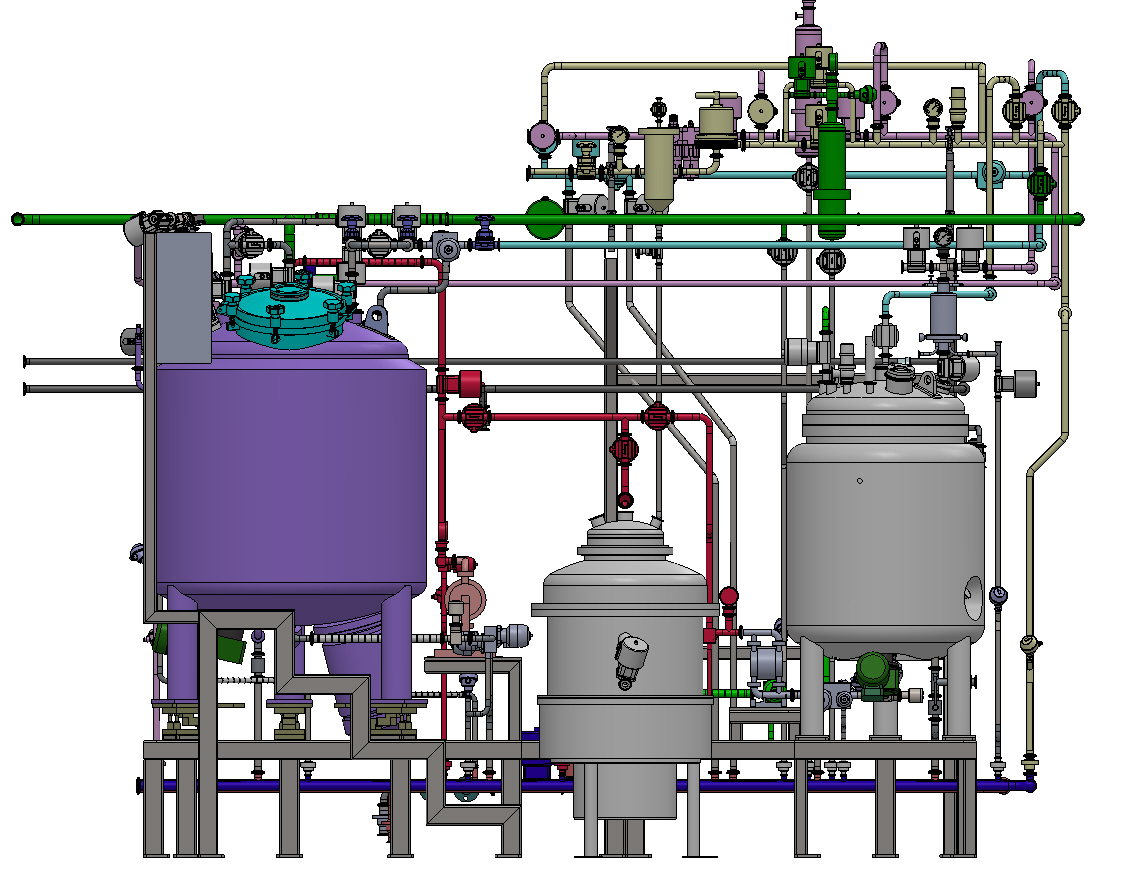

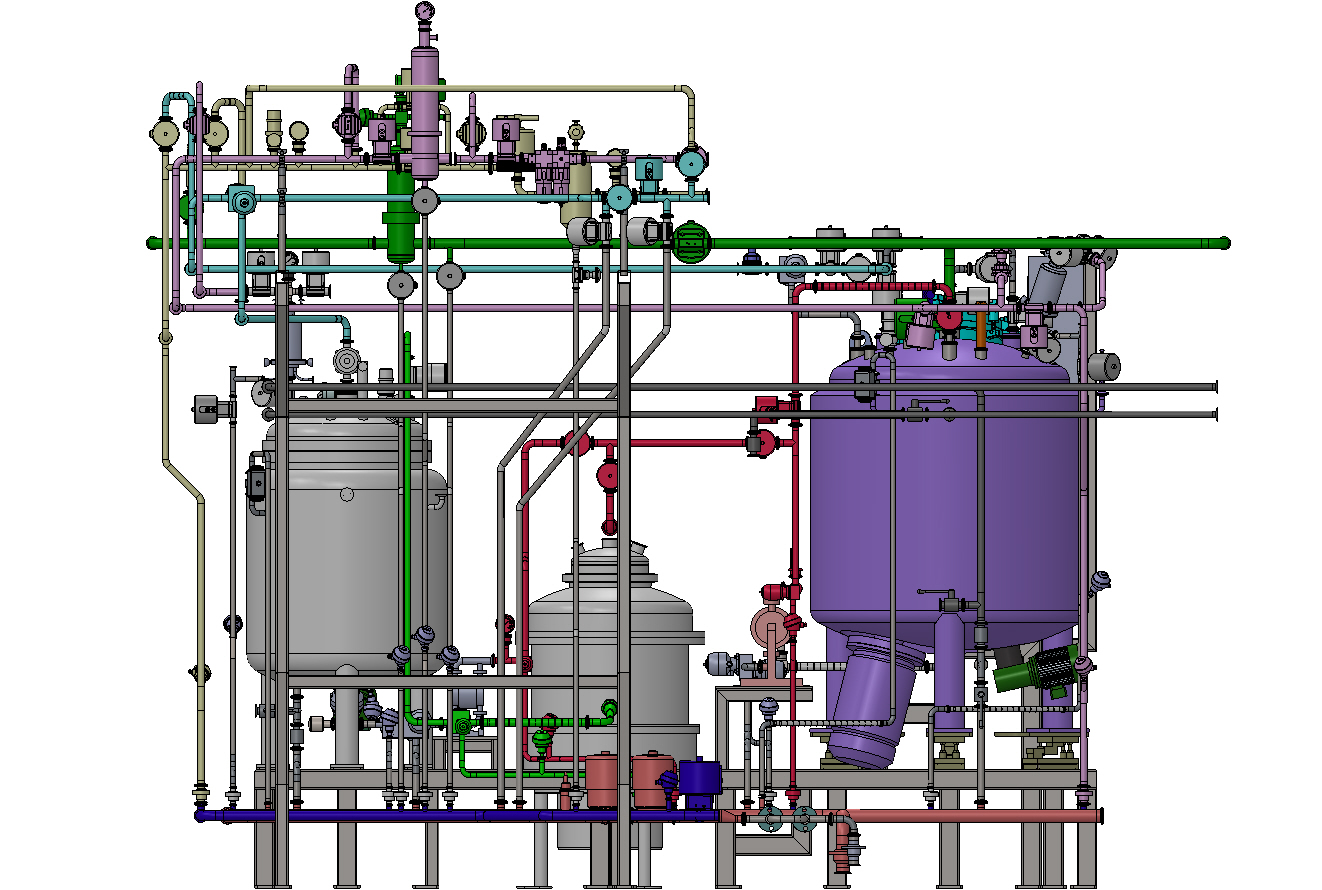

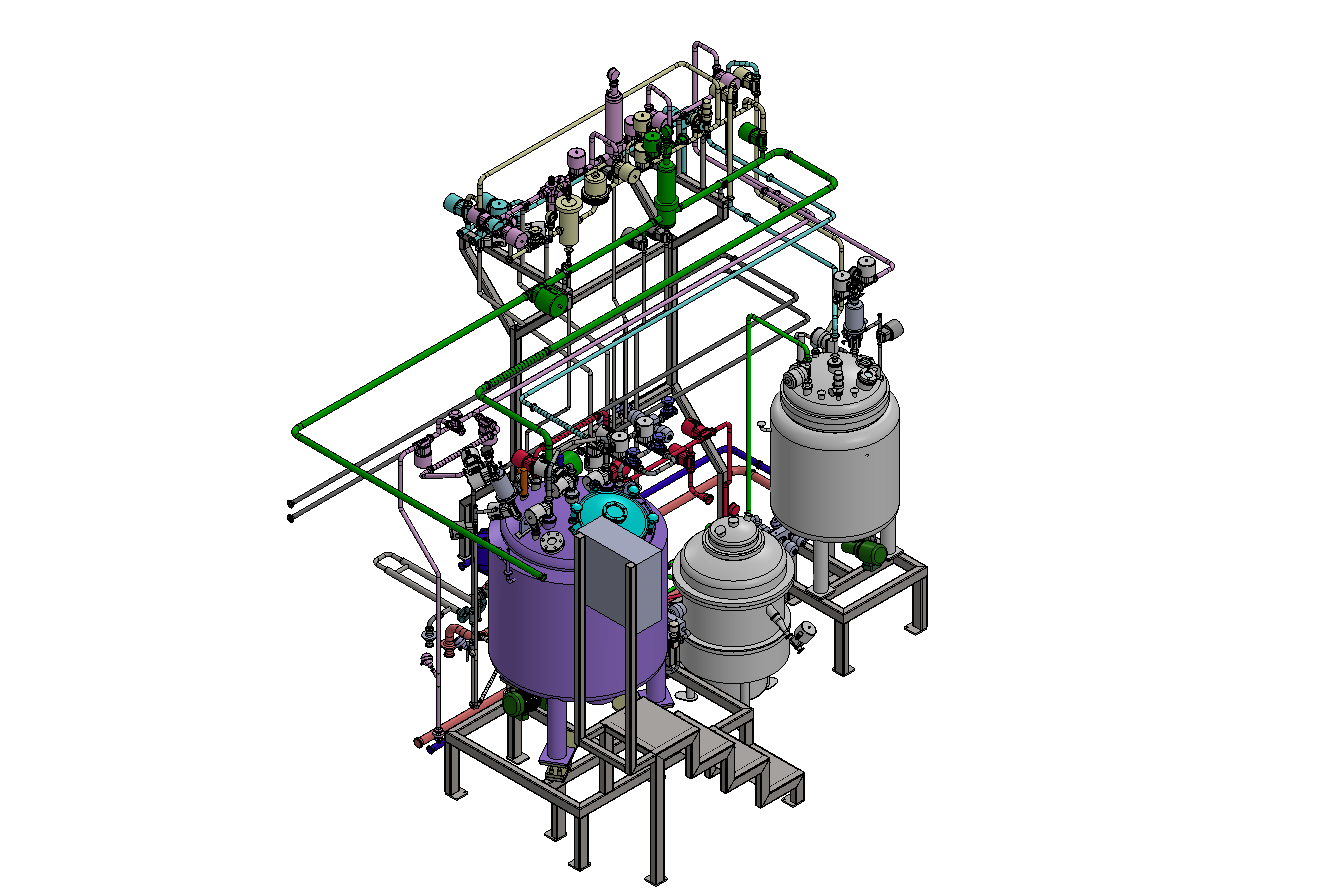

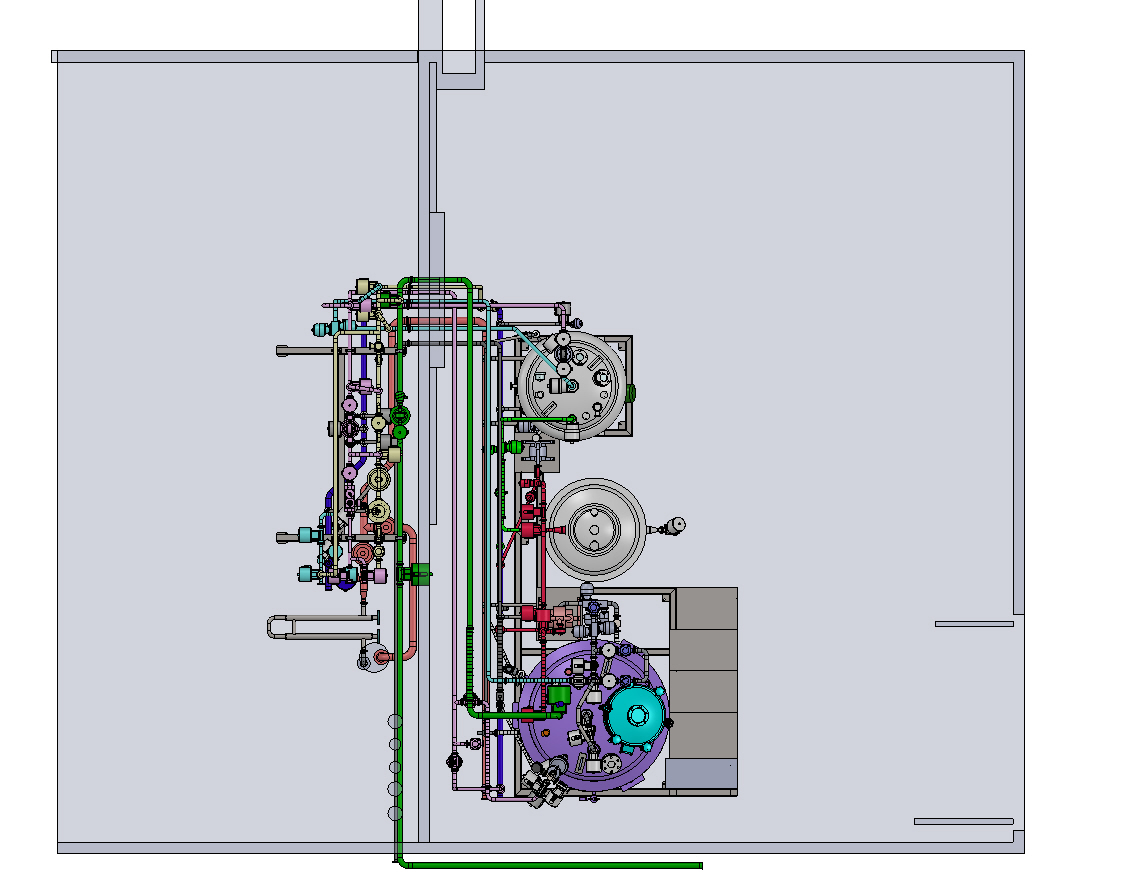

Description

Pharmatech has the experience and know-how to offer optimal solutions for your liquid processing. We have 35+ years experience as a reputed supplier of all types of liquid formulations processes forApplications

Design, Construction, Validation for Sterile Processing

Pharmatech, a leader in providing advanced processing solutions for pharmaceutical liquids application.

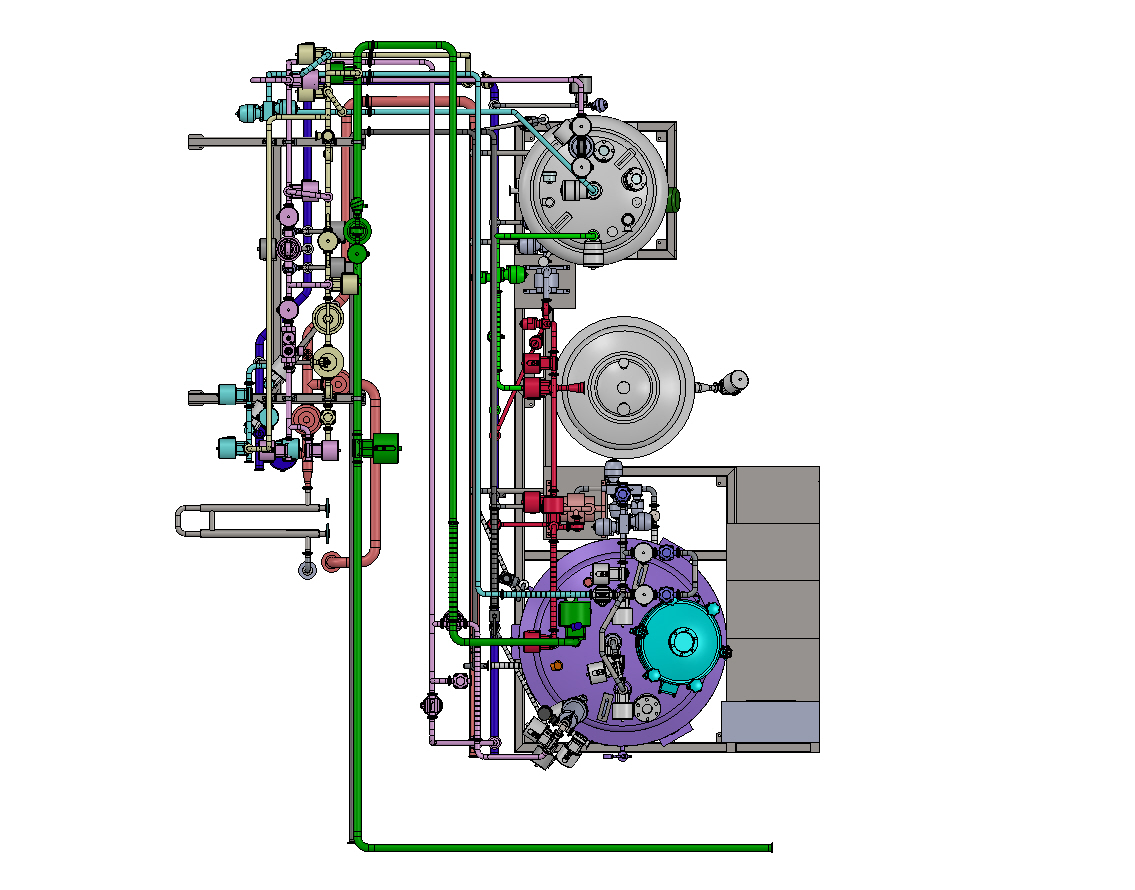

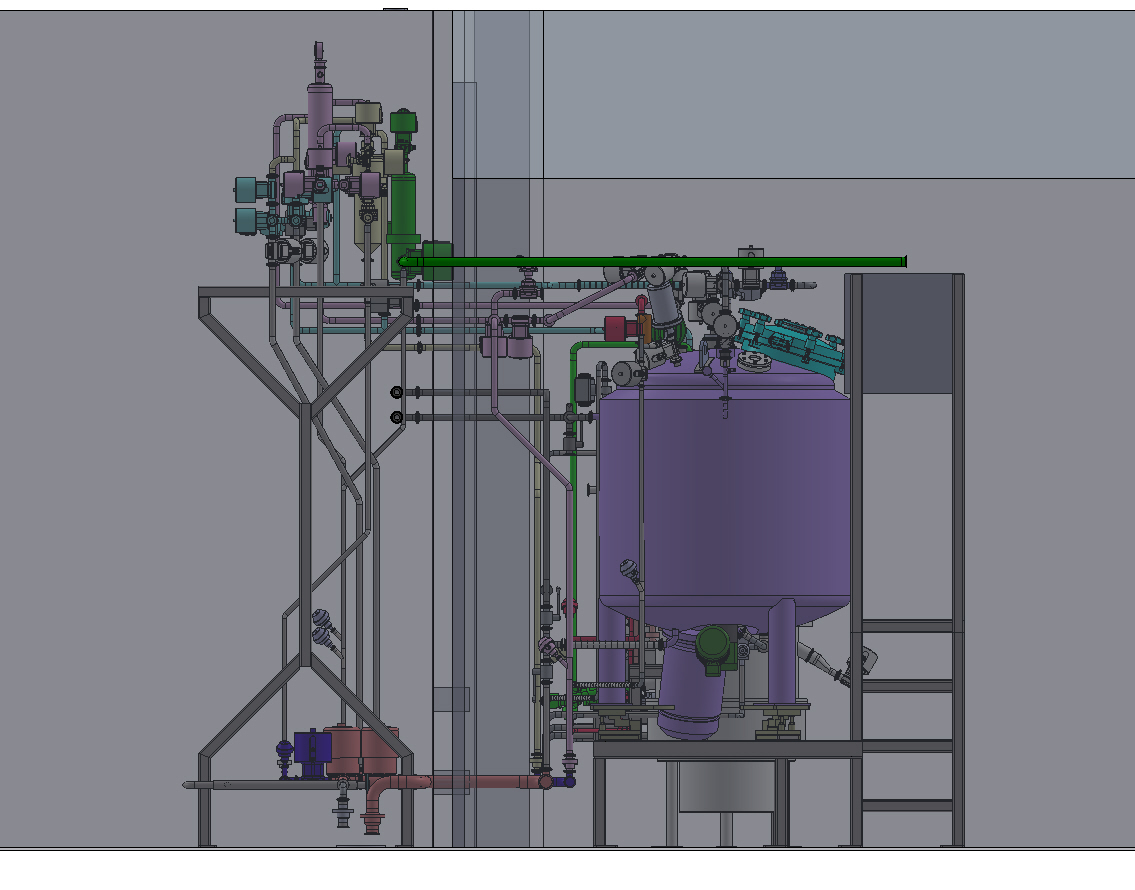

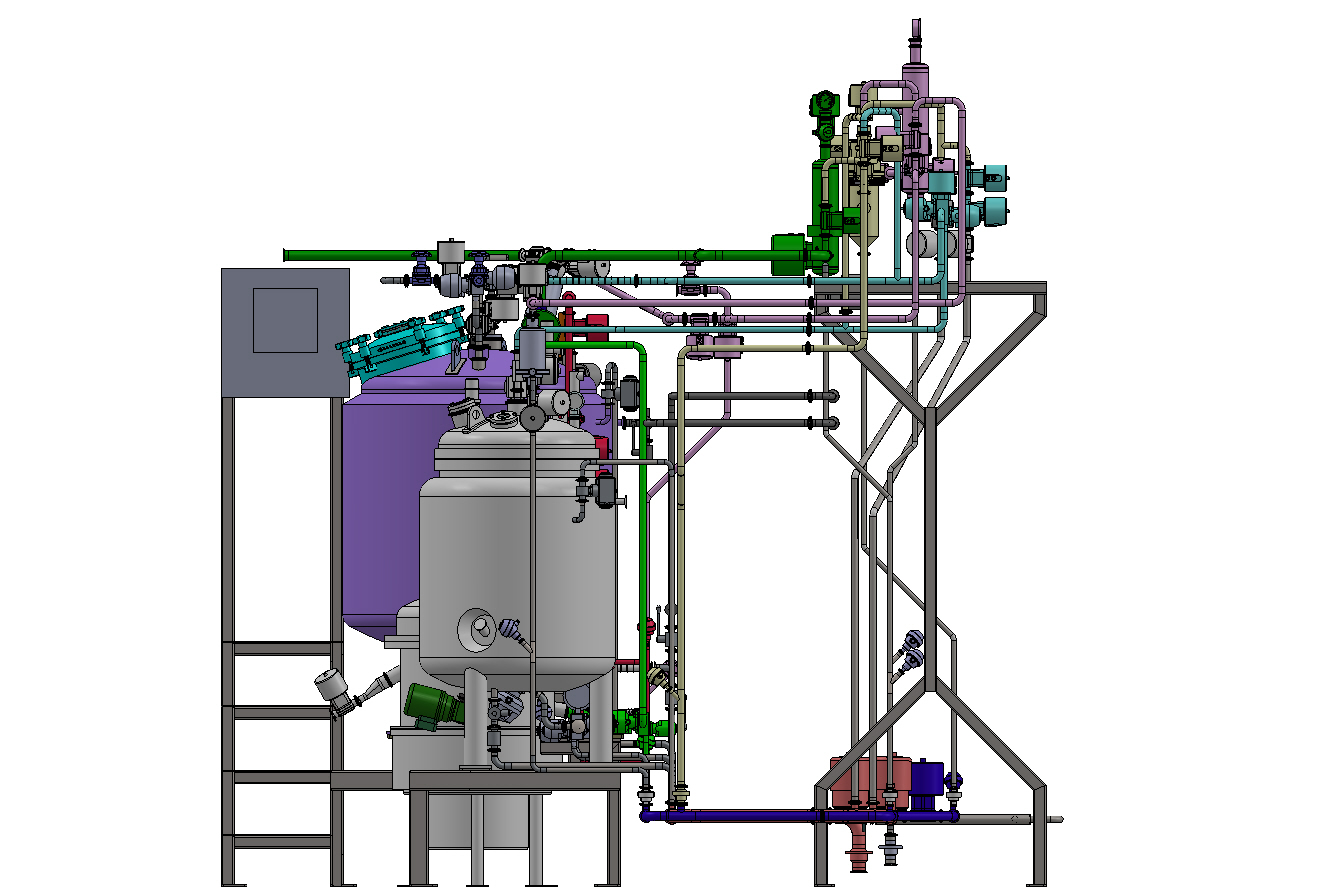

We design and build according to specifications and requirements (URS) for Sterile Design following cGMP, Good Engineering Practice for individual piece of equipment to complete integrated plants.

System is designed with latest components and value technology using required appropriate criteria.

Control options from simple, manual push button control to full Programmable Logic Controller (PLC) based SCADA options, offering a wide range of recipe handling, Data Acquisition and networking functions compliance to 21 CFR part -11 and Supervisory Control Systems.

Typical system includes both Clean in Place (CIP) & Steam in Place (SIP) requirements. CIP & SIP operations are complimentarily parallel design requirements for CIP & SIP leading to integrated solutions which results in optimized equipment design.

Design feature

- Sterile, Steri-flange connections for zero dead leg & efficient CIP cleaning of all top lid connections during CIP cleaning cycle & validations.

- Spray ball for CIP cleaning of tank with proper distribution of cleaning liquid

- Sight & Light glass – Halogen / LED lamp for proper viewing with optional camera provision to view on HMI screen

- Sterile sampling valve on side wall of vessel with steri-flange & insitu CIP-SIP able sampling valve

- Zero dead leg bottom outlet valve with optional provision of sample taking valve.

- Magnetic stirrer for mixing, option of gentle mixing 0 - 400 RPM, High speed stirrer 0 - 1400 RPM & Homogenizer 0 -2800 depending on required process applications.

- Vent filter with electrical / Steam jacket for hydrophobic sterile filter

- Laser welded pillow jacket for heating / cooling applications for fast heat transfer

- Dual insulation vessel side wall & bottom

- Load cell for volume / Weight measurement with SS Skid

- Product transfer by nitrogen / sterile air / Peristaltic pump with filtration skid & insitu CIP / SIP provision

- Individual vessel skid or complete process plant with skidded system with all piping and cabling system with panel board assembly of time at site & reduce project start time.

- FAT of complete system offered in our new dust free area with all utilities in place

- Documentation DQ/IQ/OQ, Functional specification of automation system.

- SAT- Qualified team service & automation engineering to offer Assembly and product trials to the complete satisfaction of client in minimum possible time.

- After sales service

- Integration of client free issue material like centralized H & C system, high pressure homogenizer & sterile ANFD is offered upon request and discussion during techno commercial finalization

- In house automatic polishing and buffing, with electro polishing facility ensures internal finish < 0.4 m Ra with certification